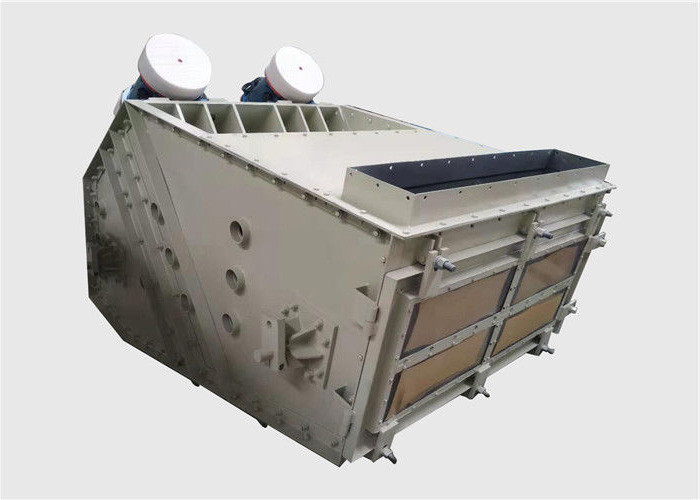

Mineral Powder Rectangular Vibrating Screen Self Cleaning Double Deck

Introduction of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder is a kind of new and efficient sieving equipment, which bears a linear track of its screen-box movement. Using multi layers large angle sieve surface, the angle of screen mesh surface are increased from top to bottom, the size of sieve pore is large than required for sieving granularity in accordance with the using of probability theory, and it is 1.2-2.2 times than required granularity usually, greatly improving the sieving efficiency and productivity. This is series is a successful model by the organic combination of probability theory with engineering practice. The probability screen has an almost perfect performance because of its totally novel concept of design and its unique structure and screening fundamentals so that there lays an extensive prospect for its application.

Working Principle of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

AG series probability sieve adopts the sieve pore which is bigger than sieving granularity; it carries on grading of materials. It is formed by the framework, and two screen mesh surfaces which is a group of multi layers overlap, the angles of the screen surface are increased from top to bottom, and the increasing the gradient from top to bottom, decreasing the size of the mesh pore and two motors. The entire equipment is installed in a group of the flexible originals. and the mesh surface can get high-frequency vibration through vibrating motor rotation. The mesh size is usually bigger than sieving granularity, and when the materials enter into machine, they will be disintegrated quickly, eliminating the blockage phenomenon which way be caused by close mesh particles.

Characteristics of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

1. High Output

Probability screen capacity can reach more than 80 tons per hour, one set probability screen capacity equal multiple sets ordinary vibrating sieve, layout is easier in site .

2. Multi-level Classification

Multi-level classification for mechanism sand or natural sand, screening mesh: 5mm ~ 2.36mm ~ 1.2mm ~ 0.6mm, some of the special mortar has been screened to 0.3mm ~ 0.15mm ~ 0.075mm.

3. Cost-effective

Introduced advanced technology from Germany and Spain, etc, continuous R & D and site validation, the probability screen successfully replace the expensive imported equipment in the dry mortar production line.

4. Longer Life Expectancy

Screen surface design is curved state, the external ratchet tension can easily control the screen surface tension without loose, to make the screen mesh with longer life.

5. Unique Structure

Closed multi-layer design, up to five layers can be designed, and change the mesh faster, the back of the machine and the front of the discharge port are all detachable design, you can quickly replace each layer of mesh.

6. Green Environmental Protection

Probability Screen Equipment Cover designed with dust removal device, it can be easily connected to the site dust removal equipment to achieve dust-free screening requirements.

Main Dimensions of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

| Model |

L |

L1 |

L2 |

B |

B1 |

H |

| AG-0818 |

1800 |

1100 |

260 |

820 |

1160 |

1800 |

| 2AG-0818 |

1800 |

1100 |

260 |

820 |

1160 |

1900 |

| AG-1020 |

2000 |

1250 |

300 |

1020 |

1380 |

1850 |

| 2AG-1020 |

2000 |

1250 |

300 |

1020 |

1380 |

1980 |

| AG-1024 |

2400 |

1550 |

300 |

1020 |

1380 |

2050 |

| 2AG-1024 |

2400 |

1550 |

300 |

1020 |

1380 |

2150 |

| 3AG-1024 |

2400 |

1550 |

300 |

1020 |

1380 |

2400 |

| AG-1030 |

3000 |

2000 |

300 |

1020 |

1380 |

2200 |

| 2AG-1030 |

3000 |

2000 |

300 |

1020 |

1380 |

2350 |

| AG-1224 |

2400 |

1550 |

380 |

1230 |

1620 |

2050 |

| 2AG-1224 |

2400 |

1550 |

380 |

1230 |

1620 |

2200 |

| 3AG-1224 |

2400 |

1550 |

380 |

1230 |

1620 |

2450 |

| AG-1230 |

3000 |

2000 |

380 |

1230 |

1620 |

2200 |

| 2AG-1230 |

3000 |

2000 |

380 |

1230 |

1620 |

2350 |

| 3AG-1230 |

3000 |

2000 |

380 |

1230 |

1620 |

2600 |

| AG-1236 |

3600 |

2350 |

380 |

1230 |

1620 |

2350 |

| 2AG-1236 |

3600 |

2350 |

380 |

1230 |

1620 |

2500 |

| AG-1530 |

3000 |

2000 |

450 |

1530 |

1930 |

2200 |

| 2AG-1530 |

3000 |

2000 |

450 |

1530 |

1930 |

2350 |

| 3AG-1530 |

3000 |

2000 |

450 |

1530 |

1930 |

2600 |

| AG-1536 |

3600 |

2350 |

450 |

1530 |

1930 |

2350 |

| 2AG-1536 |

3600 |

2350 |

450 |

1530 |

1930 |

2600 |

| AG-1836 |

3600 |

2350 |

500 |

1830 |

2300 |

2400 |

| 2AG-1836 |

3600 |

2350 |

500 |

1830 |

2300 |

2550 |

| 3AG-1836 |

3600 |

2350 |

500 |

1830 |

2300 |

2810 |

| AG-1842 |

4200 |

2800 |

500 |

1830 |

2300 |

2560 |

| 2AG-1842 |

4200 |

2800 |

500 |

1830 |

2300 |

2720 |

Main Technical Parameters of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

| Model |

Layer |

Screen Area

(m2)

|

Screen Aperture

(mm)

|

Feed Size (mm) |

Capacity

(t/h)

|

Double Amplitude (mm) |

Shake Frequency

(r/min)

|

Power (KW) |

Max. Vibration Force (KN) |

| AG-0818 |

1 |

1.44 |

0.25-6 |

≤40 |

1.5-20 |

6-8 |

980 |

0.75×2 |

10×2 |

| 2AG-0818 |

2 |

1.44 |

0.25-12 |

≤40 |

2-40 |

6-8 |

980 |

0.75×2 |

10×2 |

| AG-1020 |

1 |

2 |

0.25-6 |

≤50 |

2-30 |

6-8 |

980 |

1.1×2 |

16×2 |

| 2AG-1020 |

2 |

2 |

0.25-12 |

≤50 |

2.5-60 |

6-8 |

980 |

1.1×2 |

16×2 |

| AG-1024 |

1 |

2.4 |

0.25-6 |

≤50 |

2.5-45 |

6-8 |

980 |

1.1×2 |

16×2 |

| 2AG-1024 |

2 |

2.4 |

0.25-12 |

≤50 |

3-80 |

6-8 |

980 |

1.5×2 |

20×2 |

| 3AG-1024 |

3 |

2.4 |

0.25-12 |

≤50 |

4-100 |

6-8 |

980 |

1.5×2 |

20×2 |

| AG-1030 |

1 |

3 |

0.25-6 |

≤50 |

3-60 |

6-8 |

980 |

1.5×2 |

20×2 |

| 2AG-1030 |

2 |

3 |

0.25-12 |

≤50 |

4-100 |

6-8 |

980 |

1.5×2 |

20×2 |

| AG-1224 |

1 |

2.88 |

0.25-6 |

≤80 |

3-60 |

6-8 |

980 |

1.5×2 |

20×2 |

| 2AG-1224 |

2 |

2.88 |

0.25-12 |

≤80 |

4-100 |

6-8 |

980 |

2.2×2 |

30×2 |

| 3AG-1224 |

3 |

2.88 |

0.25-12 |

≤80 |

5-120 |

6-8 |

980 |

2.2×2 |

30×2 |

| AG-1236 |

1 |

4.32 |

0.35-6 |

≤80 |

6-100 |

6-8 |

980 |

2.2×2 |

30×2 |

| 2AG-1224 |

2 |

4.32 |

0.35-12 |

≤80 |

8-150 |

6-8 |

980 |

2.2×2 |

30×2 |

| AG-1230 |

1 |

3.6 |

0.25-6 |

≤80 |

4-80 |

6-8 |

980 |

1.5×2 |

20×2 |

| 2AG-1230 |

2 |

3.6 |

0.25-12 |

≤80 |

5-120 |

6-8 |

980 |

2.2×2 |

30×2 |

| 3AG-1230 |

3 |

3.6 |

0.25-12 |

≤80 |

6-150 |

6-8 |

980 |

2.2×2 |

30×2 |

| AG-1530 |

1 |

4.5 |

0.35-6 |

≤100 |

6-100 |

6-8 |

980 |

2.2×2 |

30×2 |

| 2AG-1530 |

2 |

4.5 |

0.35-12 |

≤100 |

8-150 |

6-8 |

980 |

3.0×2 |

40×2 |

| 3AG-1530 |

3 |

4.5 |

0.35-12 |

≤100 |

10-180 |

6-8 |

980 |

3.0×2 |

40×2 |

| AG-1536 |

1 |

5.4 |

0.35-6 |

≤100 |

8-120 |

6-8 |

980 |

3.0×2 |

40×2 |

| 2AG-1536 |

2 |

5.4 |

0.35-12 |

≤100 |

10-200 |

6-8 |

980 |

3.0×2 |

40×2 |

| AG-1836 |

1 |

6.48 |

0.35-6 |

≤120 |

12-150 |

6-8 |

980 |

3.7×2 |

50×2 |

| 2AG-1836 |

2 |

6.48 |

0.35-12 |

≤120 |

16-250 |

6-8 |

980 |

3.7×2 |

50×2 |

| 3AG-1836 |

3 |

6.48 |

0.35-12 |

≤120 |

20-300 |

6-8 |

980 |

3.7×2 |

50×2 |

| AG-1842 |

1 |

7.56 |

0.35-6 |

≤120 |

15-200 |

6-8 |

980 |

3.7×2 |

50×2 |

| 2AG-1842 |

2 |

7.56 |

0.35-12 |

≤120 |

20-300 |

6-8 |

980 |

3.7×2 |

50×2

|

Application of High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

Building materials industry: dry powder mortar, mechanism sand, natural sand, quartz sand, perlite, dolomite, calcite, potassium feldspar, etc.

Food industry: grading of granulated sugar, raw salt and edible salt.

Other industries: the size of the particle material of size 0.5~10mm and the loose density > 0.8 is the best.

Selection Tips About High-efficiency Vibrating Probability Mogensen Screens for Mineral Powder:

1. It has two kinds of vibration source forms: vibration motor and exciter, which are used for different operating environment requirements. When choosing, please determine the voltage system and whether there is explosion-proof requirement or not.

2. The high efficiency vibration probability screen installation method has several forms, such as seating type, hanging type and the combination of the two kinds. Please consider it carefully when selecting.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!